As an experienced immersion cooling manufacturer, we established the brand Box Technology to provide miners worldwide with high-quality immersion cooling systems at the most affordable prices.

In order to achieve a household name, we are committed to providing the highest quality and energy-efficient products that allow our customers to maximize the reward in the cryptocurrency mining progress.

For Box Technology Team, not only is it important to provide quality products, but it is also essential to guide the pre-operation inspection of the products. In today’s article, we will take the 120KW immersion cooling freezer for example to describe our pre-operation inspection in more detail below:

Step 1: Circulatory System Inspection

First, remove the backboard and all 29 screws.

After opening, because of long-distance transportation, we need to check there is no loose pipe connection. If there is looseness, we can tighten them with pliers.

Step 2: Pre-charge Inspection

After finishing the circulatory system inspection, we are going to do a pre-charge inspection:

First, we have to open the top cover.

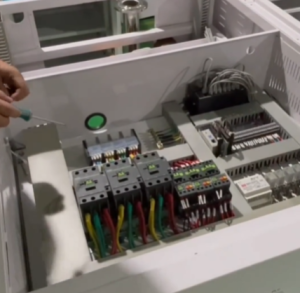

Long-distance transportation may loosen our electrical components. Thus, we need to check it.

After the component inspection, we are going to make the main connection. Connect the wires in order according to the corresponding colors and fasten. Then, we need to connect the network cable.

After the main power is connected, we open the oil tank and draw the oil tank to put in the miners. Then, plug in the power cable and network cable. After these, pour into the oil which should be over 10cm of the server.

Step 3: Power on the Machine

First, power on the PLC.

Then, start the circulation pump: pump1, pump2, pump3.

Step 4: Check All Piping Connections

When the circulating pump works well. Check all piping connections to make sure there is no leakage.

More pre-operation inspection of the 120KW immersion cooling freezer will be continued in the next update.